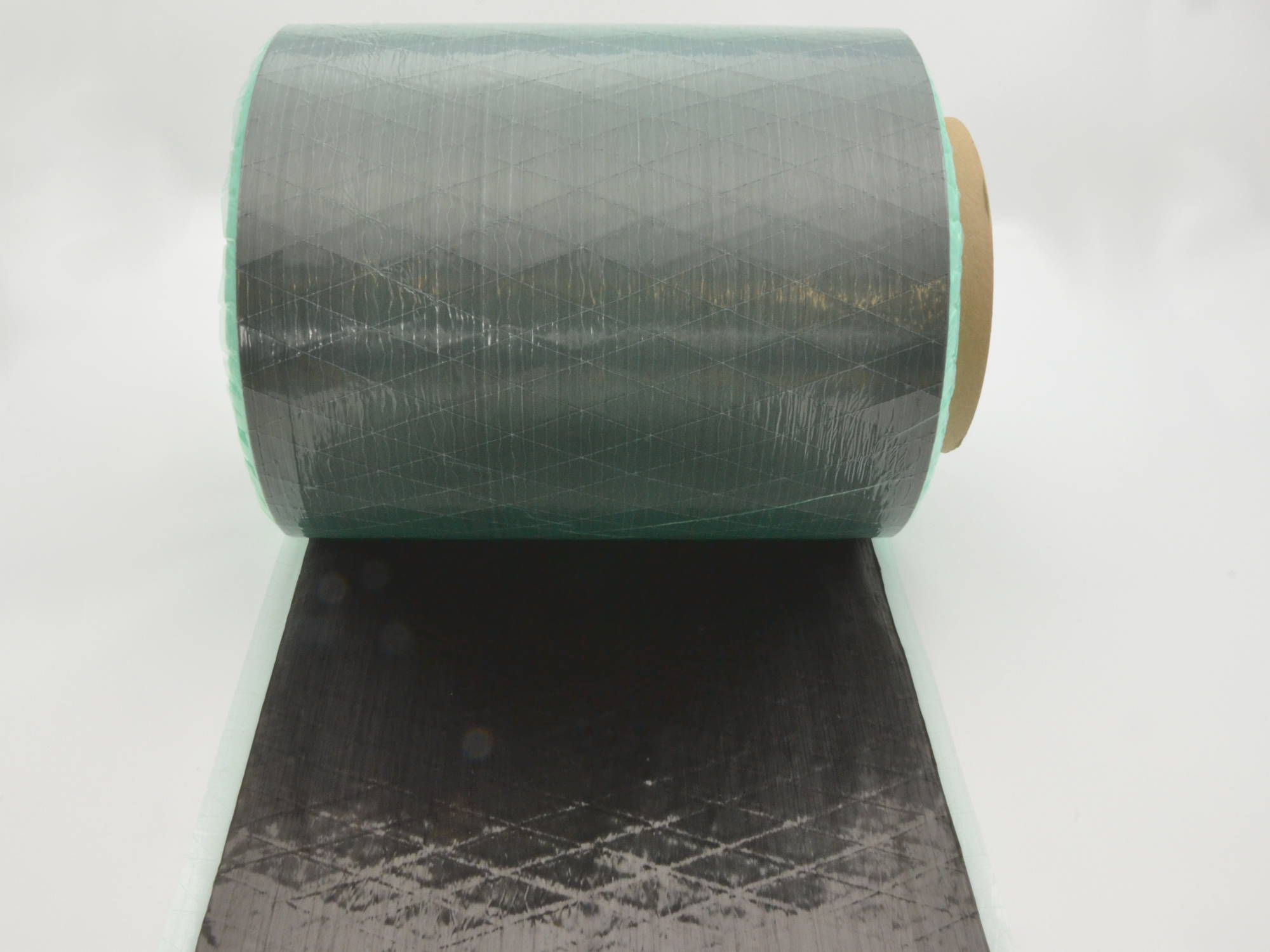

Carbon fibre UD non-crimp fabrics

| Benefits:

|

Standard range of UD non-crimp fabrics using HT carbon fibres

Type C-1: web on one side

Type C-2: web on both sides

Areal weight [g/m²] | Width [mm] | Style |

|---|---|---|

80 | 600 | UD C-1- 80/600 |

100 | 300 | UD C-1-100/300 |

200 | 50 | UD C-1- 200/50 |

200 | 300 | UD C-1- 200/300 |

300 | 50 | UD C-1- 300/50 |

300 | 300 | UD C-2- 300/300 |

400 | 200 | UD C-2- 400/200 |

600 | 550 | UD C-2- 600/550 |

Standard range of UD non-crimp fabrics using HM- and ultra-high modulus carbon fibres

Areal weight [g/m²] | Width [mm] | Fibre | Style |

|---|---|---|---|

100 | 300 | Pyrofil HR40 12K | HM UD C-1-100/300 |

250 | 250 | Dialead K63716 | HM UD C-2-250 |

450 | 100 | Dialead K63716 | HM UD C-2-450/100 |

450 | 200 | Dialead K63716 | HM UD C-2-450/200 |

450 | 635 | Dialead K63716 | HM UD C-2-450/635 |

Carbon fibre UD fabrics

Areal weight [g/m²] | Weave | Yarn | width [cm] | Style |

|---|---|---|---|---|

134 | UD spreaded, twill 1/3 | IM fibre | 127 | KUD134IM |

140 | UD, plain | warp 3K Carbon (120 g/m²), werft e-glass (17 g/m²) | 100 | KUD140 |

194 | UD spreaded, twill 1/3 | IM fibre | 127 | KUD194IM |

further items available on request