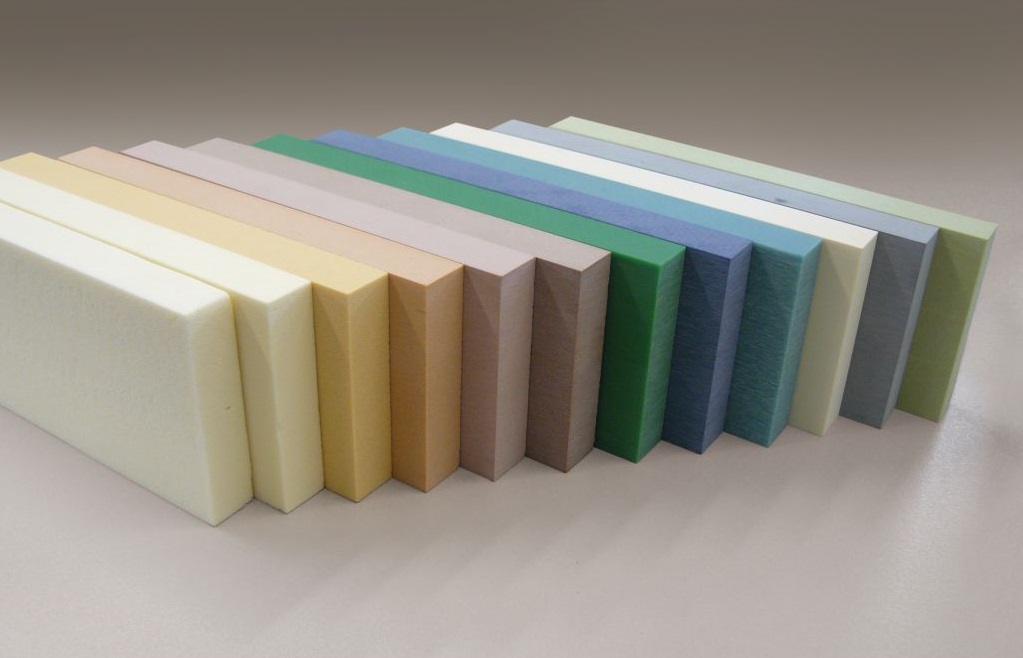

SikaBlock® tooling boards

SikaBlock® Model boards

| M80 | M330 | M600 | M700 |

Density [g/cm³] | 0,08 | 0,24 | 0,6 | 0,7 |

Colour | yellowish | siena | light brown | light brown |

Material | PUR | PUR | PUR | PUR |

Characteristics |

|

|

|

|

Applications |

|

|

|

|

Dimensions [mm]; [ltr.] |

|

|

|

|

Shore hardness | - | D 25 | D 58 | D 66 |

Flex. strength [MPa] | 1 | 5 | 19 | 26 |

Thermal resistance [°C] | 130 | 60 | 80 | 90 |

CTE αT [1/K] | 50 x 10-6 | 65 x 10-6 | 55 x 10-6 | 55 x 10-6 |

further items available on request

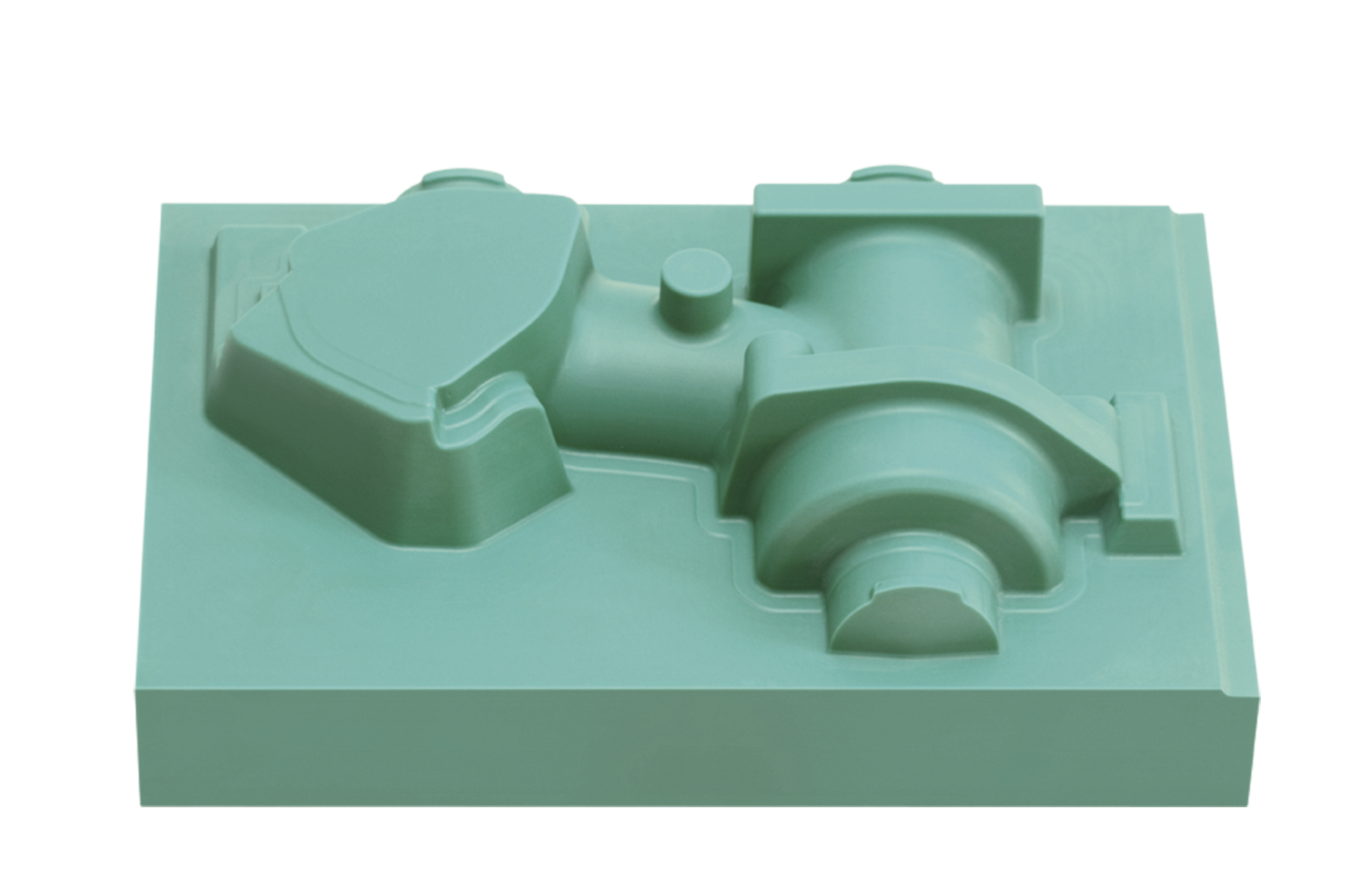

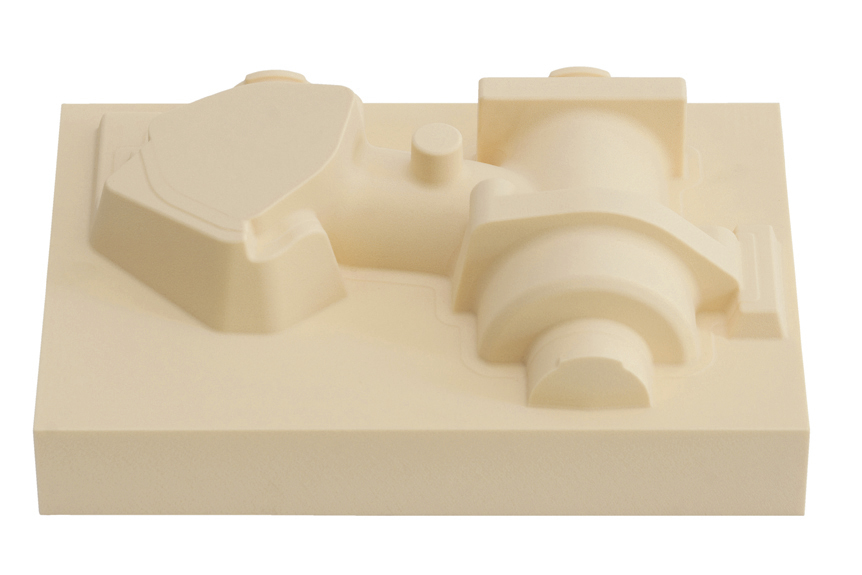

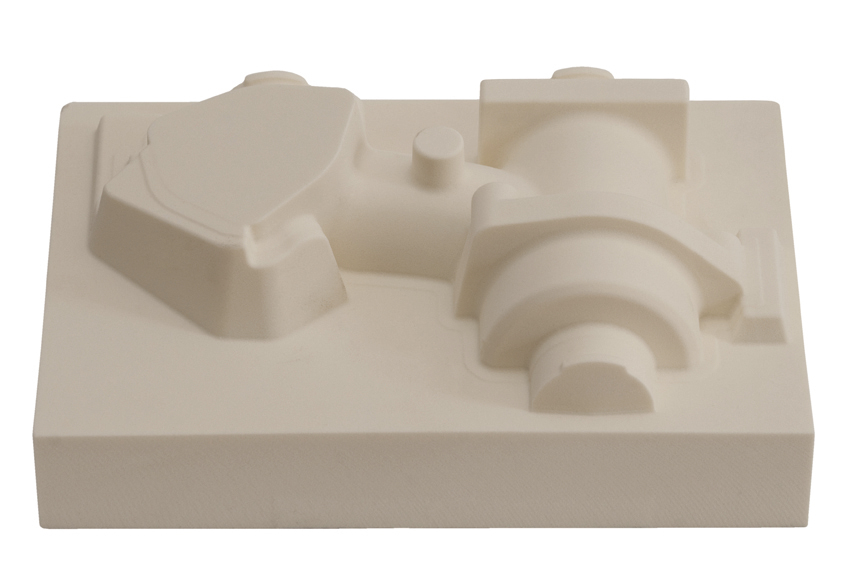

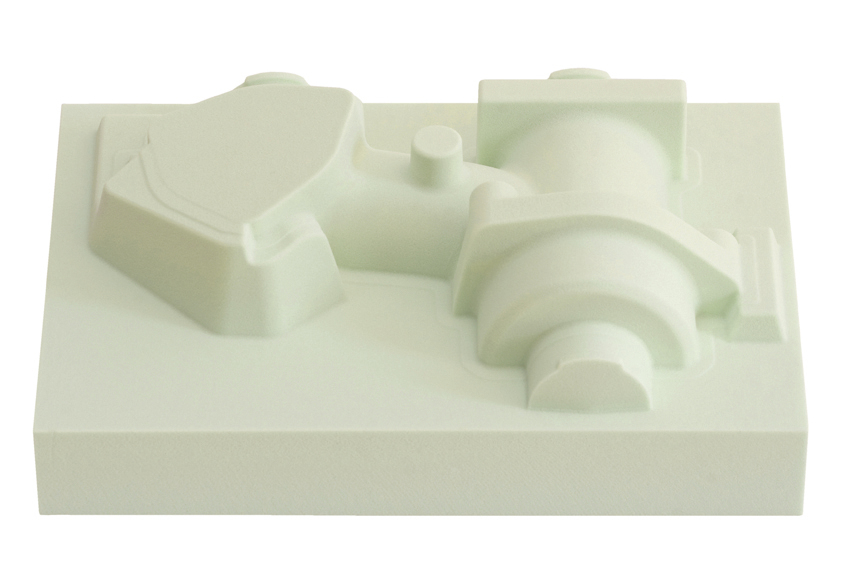

SikaBlock® Tooling Boards

M1000 | M945 | LAB 975 NEU | LAB 973 | |

Density [g/cm³] | 1 | 1,3 | 0,7 | 0,75 |

Colour | white | green | light green | blue |

Material | PUR | PUR | EP | EP |

Characteristics |

|

|

|

|

Applications |

|

|

|

|

Dimensions [mm]; [ltr.] |

|

|

|

|

Shore hardness | D 75 | D 83 | D 75 (D 68 @ 130°C) | D 73 (D 63 @ 130°C) |

Flex. strength [MPa] | 48 | 100 | 30 | 30 |

Thermal resistance [°C] | 85 | 80 | 130 | 125 |

CTE αT [1/K] | 50-55 x 10-6 | 65 x 10-6 | 35-40 x 10-6 | 35-45 x 10-6 |

further items available on request