Due to its very high specific stiffness, carbon has considerable potential for moving parts in mechanical engineering, such as linear axes on CNC machines. Our past projects include linear axes for laser cutting machines with a weight saving of 85 % compared to steel designs with the same tolerances in operation. The low thermal expansion of carbon fibre also means carbon components can be produced with high precision. Other applications include support bodies for high-speed grinding wheels, gripper arms in automation technology and structures for test stands in measurement technology.

CFRP components

Applications

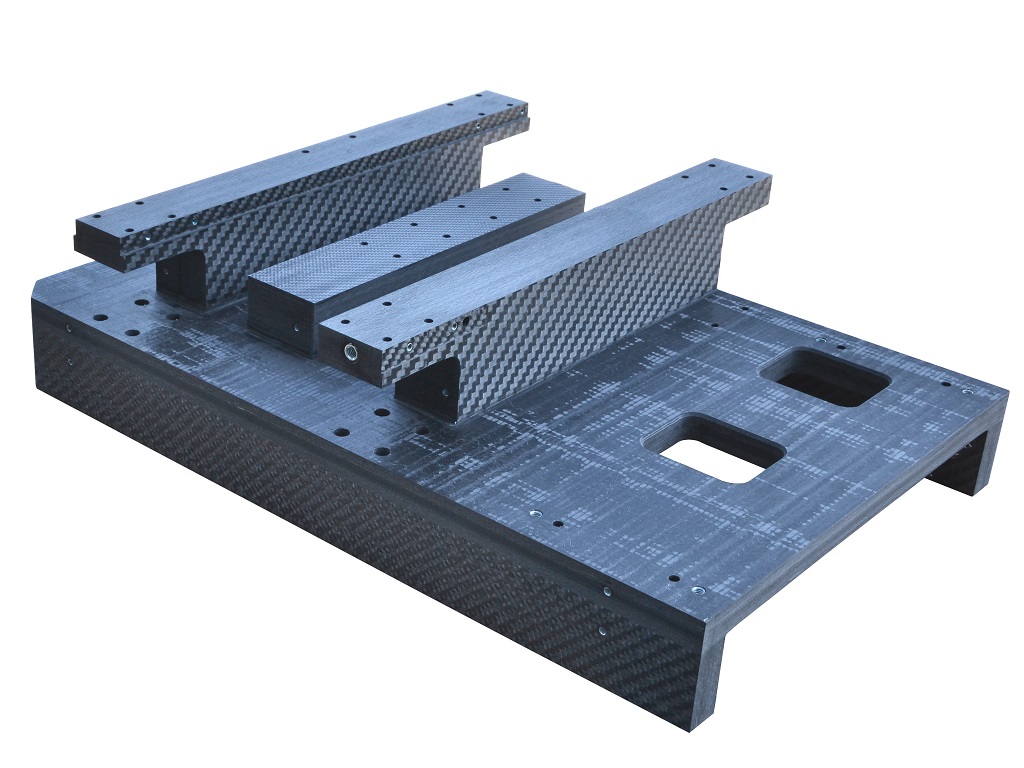

With its low weight, high stiffness and low thermal expansion, carbon offers great potential if components need to move quickly and precisely. The “Stiefelmayer effective” flatbed laser cutting machine from Stiefelmayer-Lasertechnik GmbH & Co. KG is a successful example. Productivity has been substantially increased with enhanced precision by combining linear motors, fibre lasers and a light carbon gantry for the moving y-axis, which Haufler Composites created using carbon fibre materials.

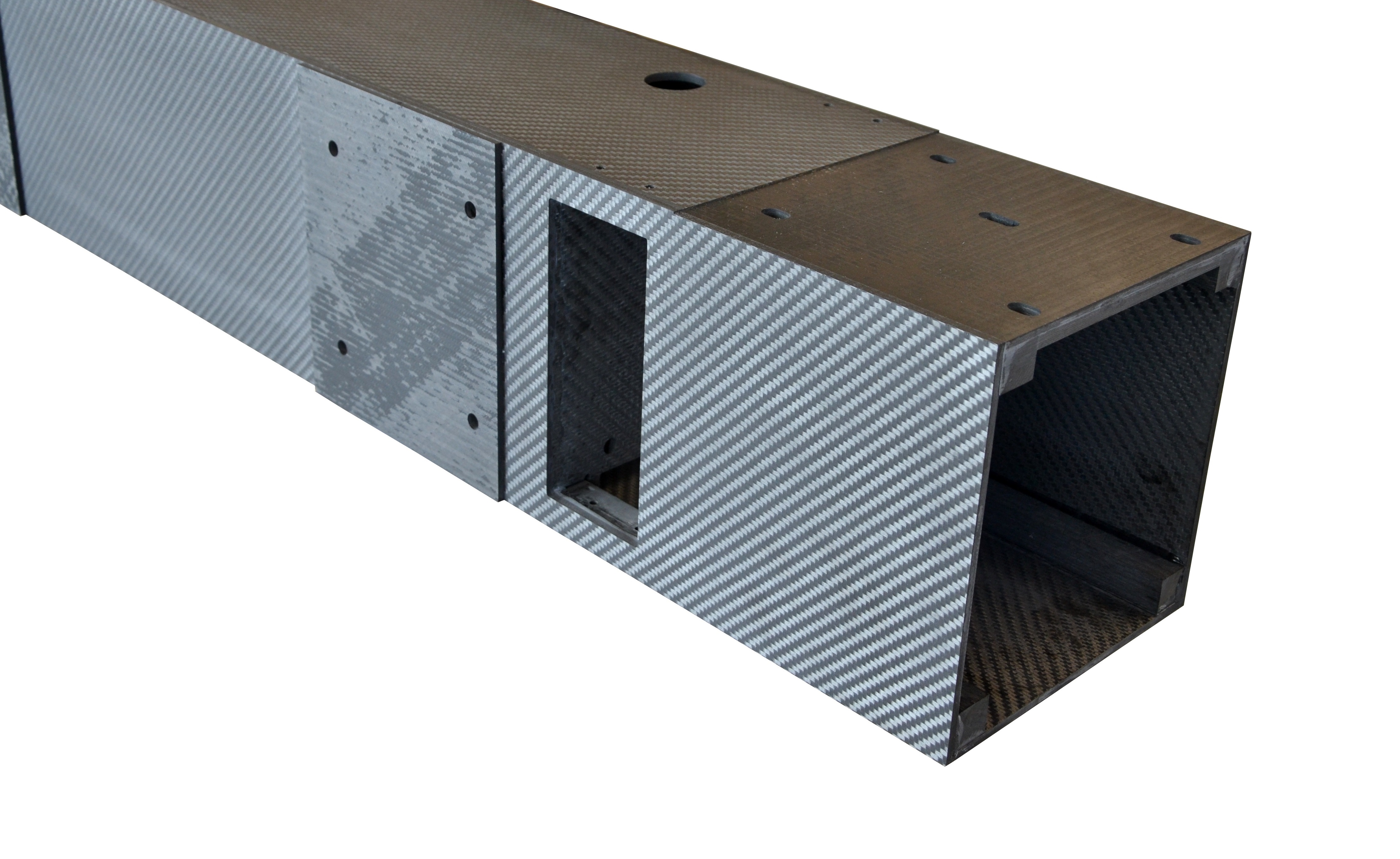

Based on the positive experience of using carbon in the “Stiefelmayer effective” range, carbon was also used for the y and z-axes of a 3D 5-axis laser cutting machine. By using high-modulus carbon fibres, the weight of the y-gantry with a length of 3.70 m was reduced by around 85 % compared to a steel design, which equates to a weight reduction of around 1,700 kg. This facilitates the very dynamic movement of the gantries using linear motors and compliance with the required precision to the hundredth of a millimetre.