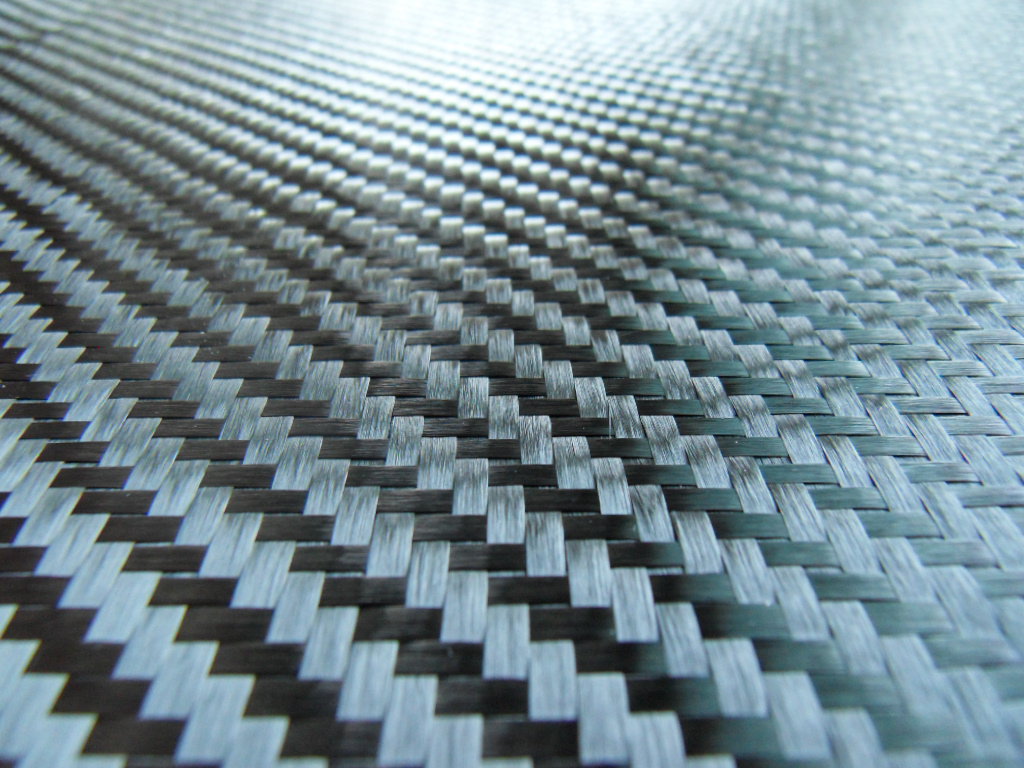

Carbon fibre

Carbon fibres are industrially produced fibres that have high specific stiffness and tensile strength. They are converted from raw materials containing carbon (normally polyacrylonitrile, also pitch for high-modulus fibres) into a special carbon structure by means of pyrolysis.

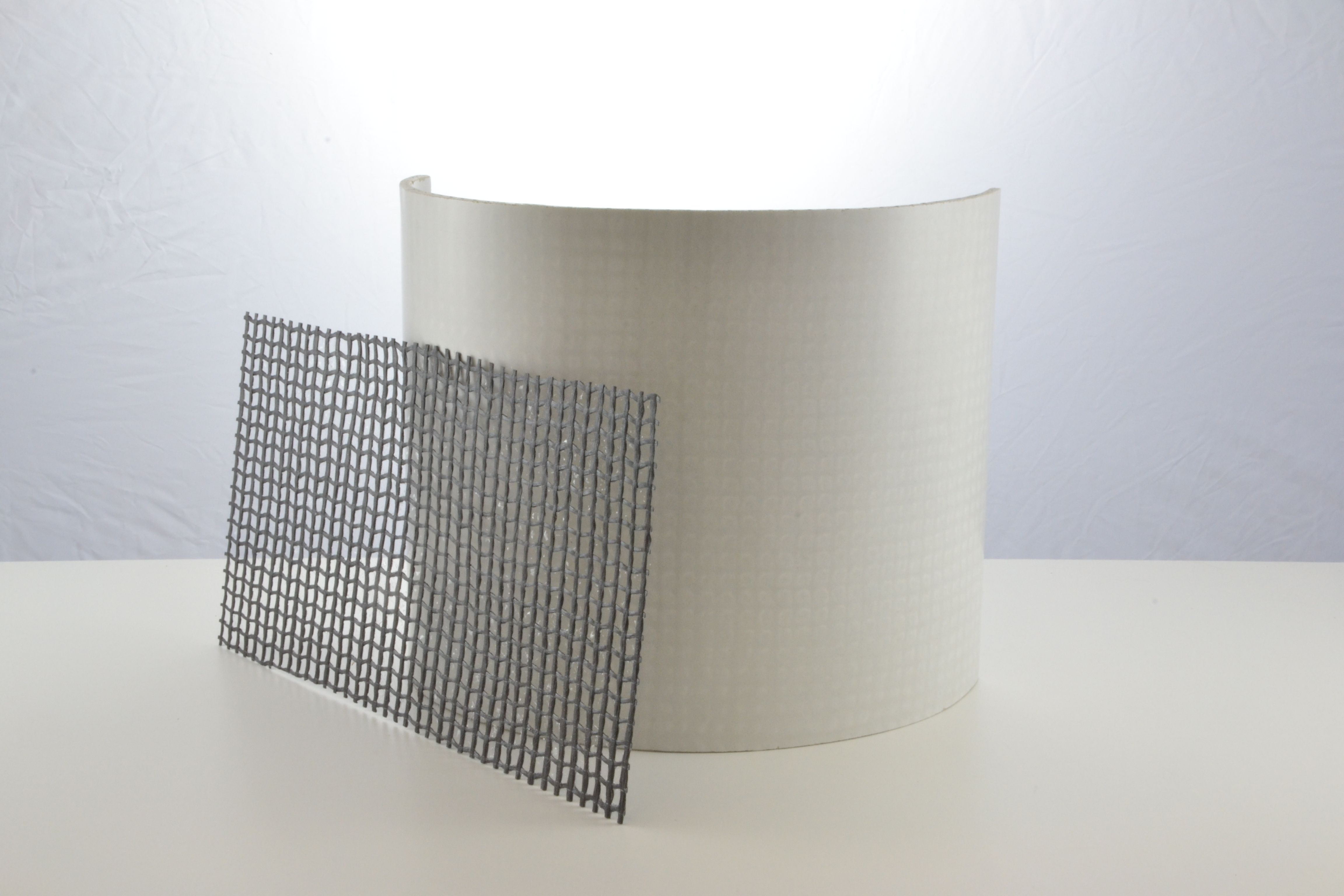

To ensure good wetting of the fibre surface on contact with liquid resin and a good connection between the hardened matrix and the fibre surface, the carbon fibre is given a finish (sizing) during the production process.

Thanks to high mechanical characteristics, carbon fibres can be used to produce light and high-quality composite components and materials. Carbon fibres can also be used to produce composite materials with almost neutral thermal expansion behaviour. Carbon fibres also conduct electricity and are transparent to X-ray.

Carbon fibres are classified according to their mechanical properties:

HT: high tenacity

IM: intermediate modulus

HM: high modulus

They are also characterised by number of filaments (1K= 1,000 filaments, 3K, 6K, 12K, 24K etc.), filament diameter, the precursor and sizing. Carbon fibres consist of approx. 96 % carbon atoms.